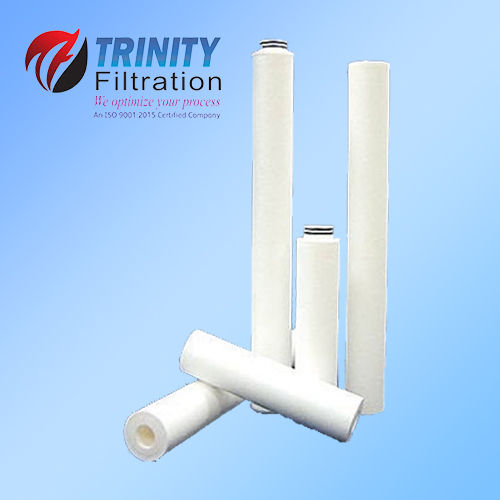

Flow-MAX Pleated Polypropylene Filters Cartridges

Product Details:

Flow-MAX Pleated Polypropylene Filters Cartridges Price And Quantity

- 50 Unit

- 700.00 INR/Unit

Flow-MAX Pleated Polypropylene Filters Cartridges Trade Information

- Thane West - Maharashtra

- 500 Unit Per Month

- 2-3 Week

- Yes

- Contact us for information regarding our sample policy

- Standard Packaging

- Maharashtra

Product Description

TRINITY Flow-MAX Pleated Filter Cartridges are designed to optimize the surface area of the PP media for higher flow rate, lower clean Delta P, and longer Service life. The Filter provides more surface area due to its pleated design. Applications for these are available across food & beverages, pharmaceutical, semiconductor and other demanding process applications. All PP construction and gradient density micro-fiber media provide excellent removal efficiencies and high contaminant holding capacities. All materials used in this filter cartridge are CFR-21 complaint so, it is safe to use for food contact purposes.

Features Of Pleated Polypropylene Filters Cartridges:

Micron Rating from 0.2 to 50 micron -Broad application range

- Low-cost

- Economic and efficient filtration.

- Optimal efficiency with a greater particle holding capacity

- 100 percent pure Polypropylene

- High efficiency filtration -99.9% (Beta 1000)

- Rigid outer cage.

|

Media |

: Polypropylene (PP) |

|

Inner Core |

: Polypropylene (PP) |

|

End Caps |

: Polypropylene (PP) |

|

Cage |

: Polypropylene (PP) |

|

Removal Ratings |

: 0.2, 0.45, 1, 2.5, 5, 10, 20, 25, 40, 50, 100 micron |

|

O Rings / Gaskets(for SOE) |

: Buna N, EPDM, Silicone, Viton, Teflon Encapsulated Viton 'O' rings. |

Dimensions:

|

Nominal Lengths |

: 9.75, 10, 20, 30, 40 inches |

|

Diameter: ID/OD |

: 1.1" (28 mm) / 2.7" (70 mm) |

|

End connections |

: DOE (standard) / SOE (optional) |

Operating Conditions

|

Max operating temperature |

:80 OC (PP) /120 OC (Cotton) |

|

Max Change Out Differential Pressure |

:75 PSID |

|

Recommended Change out differential pressure |

:40 PSID |

Application:

- PharmaceuticalPre filtration

- DIWater

- Process/ Rinse water

- FineChemicals

- Solventand gas pre filtration

- LensCoatings

- DETrap filters in Breweries

- CD/ DVD media